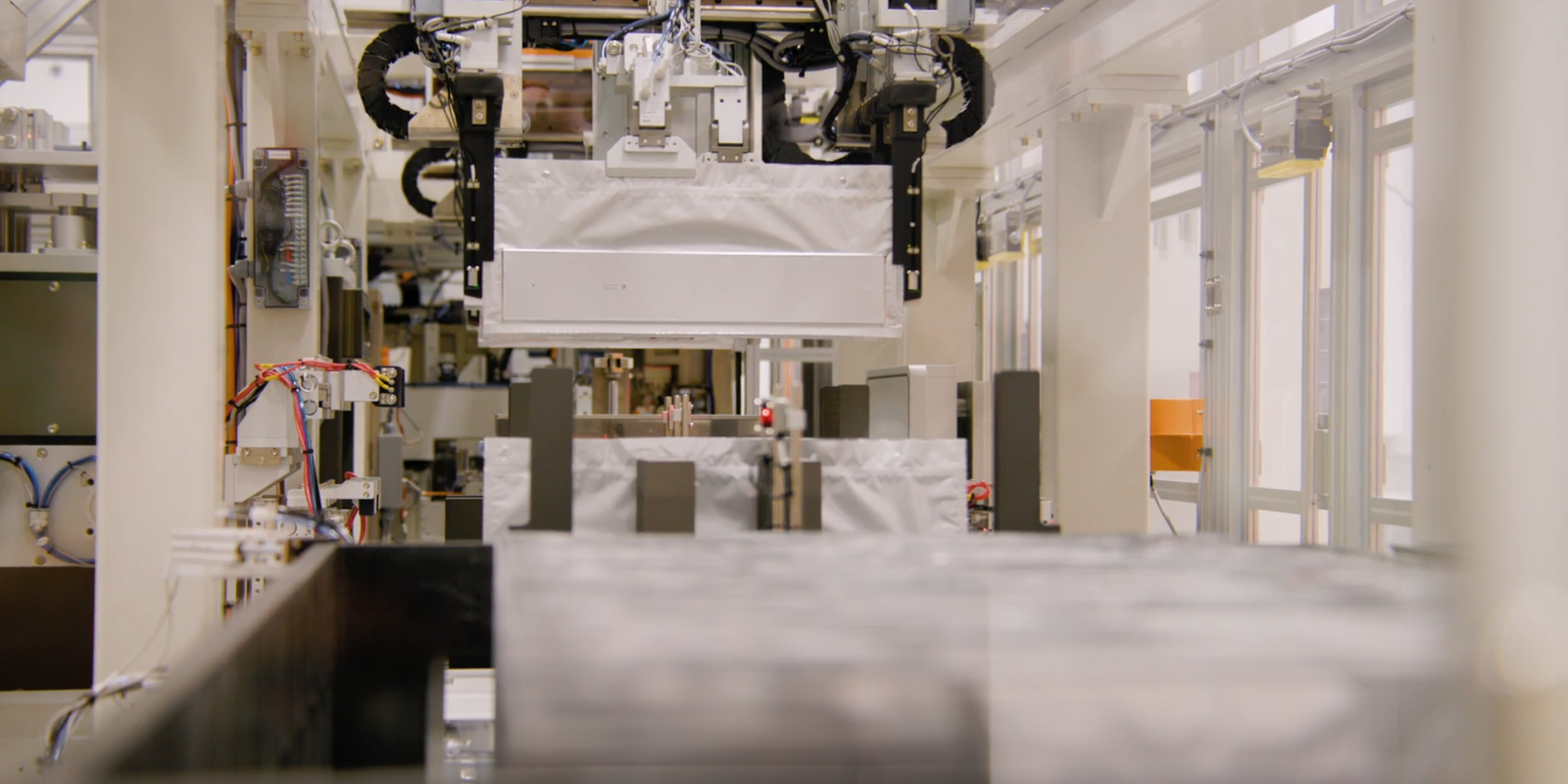

FREYR Battery Completes 80% of Standard Operating Procedures towards fully automatic production

Sep 18, 2023

Operational Excellence Drives Progress at FREYR

Today, we are pleased to announce that 80% of Standard Operating Procedures (SOPs) at FREYR’s Customer Qualification Plant (CQP) have been successfully implemented. This achievement, which is another important milestone on the path to fully automated production, is a direct result of the tireless dedication of our exceptional team, working alongside our partners and vendors in Mo i Rana.

FREYR’s operations team is now diligently finalizing the remaining SOPs towards a fully automated run of the production line at our CQP.

“At FREYR, we're unwavering in our commitment to operational excellence. Standardization is the bedrock that underpins our continuous improvement journey, ensuring efficiency and quality across every facet of our operations.

With such an important milestone in sight for the company and these priorities in mind, the team is sharply focused on implementing the Standard Operating Procedures that will unlock fully automated production”

Thomas Bergan, SVP Production, Mo i Rana

The team has been working systematically to prepare for safe and efficient production at the CQP by using Process Failure Mode and Effects Analysis (PFMEA) to identify all potential failure modes and develop a control plan to ensure quality of the product. After completing these steps, an SOP is enacted, aligning best practices with the specific task to deliver high-quality outcomes using the correct resources and maintaining a high Operating Equipment Efficiency ("OEE") threshold.

Implementing SOPs provides a basis for continuous improvement by leveraging data analysis and the powerful tools of lean manufacturing and Six Sigma methodologies.

Stay tuned for more updates as we progress towards operational excellence!